The US Department of Energy recently announced funding to a team led by NC State to develop “Ultra-low Cost, All-SiC Modular Power Converters for DC Fast Charging Equipment Connected Directly to Medium Voltage Distribution.” The goal of this project is to build on previous work at FREEDM to improve the development of electric vehicle (EV) chargers with ratings over 350 kilowatts, also known as Extreme Fast Chargers. Project partners include New York Power Authority, Danfoss, Commonwealth Edison, GoTriangle and the NC Clean Energy Technology Center.

This award from the DOE Vehicle Technologies Office builds on a current project announced in 2018, which established the design principles using DC distribution, standardized power conversion modules, and integration of energy storage and renewable generation. “The goal of this new project is to bring extreme fast charging much closer to market realization,” said Srdjan Lukic, Ph.D. and Principal Investigator for the project. “The previous project proved that we could build it. This project will optimize the overall system to make it more affordable.” Project objectives include cutting the cost in half compared to the baseline system and including the total cost of ownership in the system design.

The anticipated market for extreme fast chargers includes medium and heavy duty vehicles where asset utilization is a priority. These vehicle classes include last mile delivery vehicles, refuse trucks, school buses, and transit buses. “GoTriangle is committed to exploring the use of alternative fuels and sustainable fleet technologies so we started with two Proterra electric buses,” said Vinson Hines, Jr., Interim Chief of Operations. “Higher power charging means we can get those buses back on route even faster.”

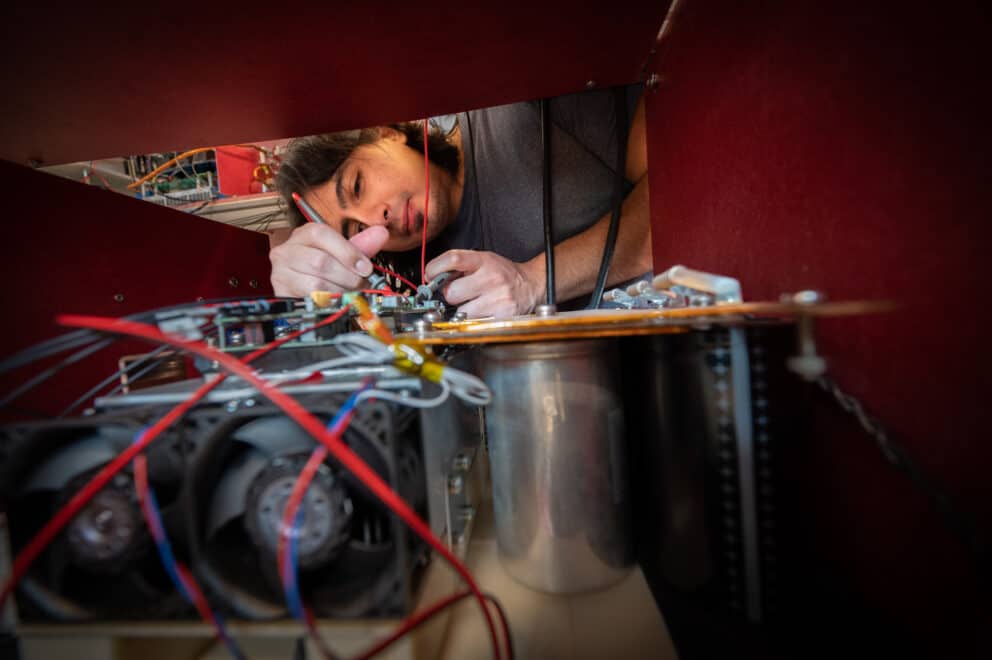

Traditional charging station designs use low voltage power electronic solutions which increase costs and decrease efficiency. But NC State and other researchers are designing extreme fast chargers that use Silicon Carbide devices and pull power from the utility distribution grid at 13,000 volts or more. Silicon carbide power electronics can operate at much higher voltages and temperatures than traditional electronics based on silicon technology. This approach eliminates the 60 hertz transformer that normally steps the grid voltage down to 480 volts. Eliminating this low frequency transformer and associated low voltage switchgear decreases the overall footprint of the extreme fast charger, which is very important for fleet owners that may have space constraints.

“NYPA is excited about this project because it will demonstrate new technology that will help New York State meet our zero emission vehicle deployment goals,” said Alan Ettlinger, Director of Research, Technology Development, and Innovation. “It will also offer lessons learned to our municipal and cooperative retailers as they deploy high power EV chargers.”

The new extreme fast charger design will include electrical and mechanical cost-cutting innovations that reduce bill of material costs and improve reliability. “FREEDM asked Danfoss to join this project because of our expertise in medium voltage power conversion,” said Dan Isaksson, Head of Medium Voltage Drives. “Building a better charging station also aligns with our corporate decarbonization goals and fleet electrification targets.”

Of course, owning and operating an EV charging station involves much more than just the hardware costs. “Other costs include permitting, land acquisition, utility infrastructure, and of course utility rates,” said Heather Brutz, Finance and Operations Manager for the Clean Transportation Program at NC Clean Energy Technology Center. “Some of these costs will influence the system design and our role is to provide insight on reducing this total cost of ownership.”

The project funding includes the development of a commercialization plan. NC State is a leader in research commercialization and ranks number 2 in the US for universities without a medical school. The University is also a leader in I-Corps, a National Science Foundation program that trains entrepreneurs to ask the right questions, determine available market size, and focus on customer pain points to develop solutions. The tech to market plan includes following the guidelines from I-Corps, networking with project partners and clean transportation organizations, and seeking licensees for intellectual property developed as part of the project.

This four year project will result in multiple prototypes installed at partner locations.